Game Gun technical specifications

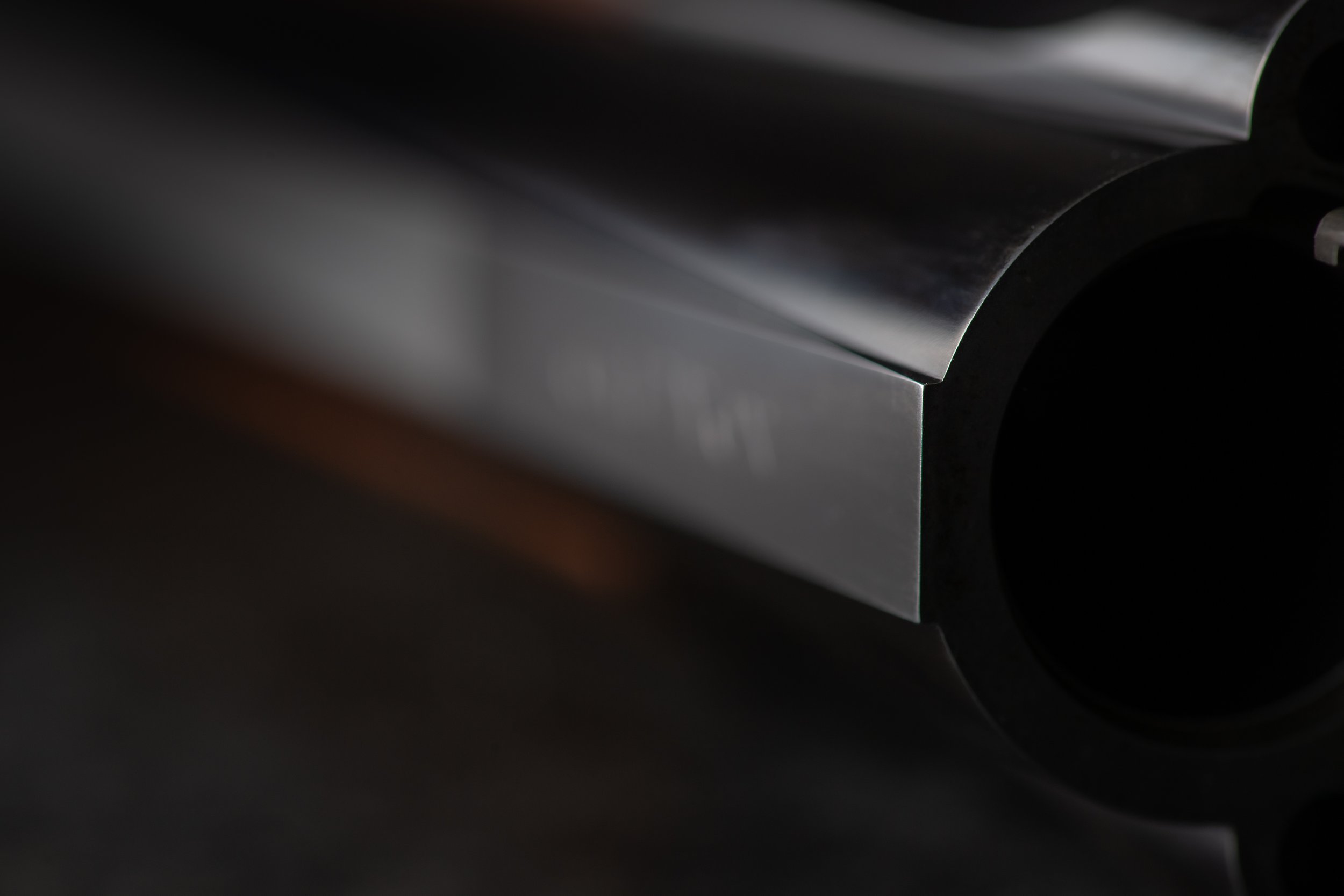

barrels

Gallyon models can be configured with either 29in, 30in or 32in barrels and are typically chambered for 3in cartridges. They are proved to 1,320 bar and bear the Fleur de Lys proof mark, the international CIP mark that denotes they are proved for High Performance steel shot. All Gallyon guns will be proved at the London Proof House.

All the barrel components are manufactured in-house to ensure the ultimate in precision, quality assurance, and performance.

The barrels are precision machined from a solid billet of chromium molybdenum steel, that offers high tensile strength and high shock load resilience.

Like every material used in Gallyon guns, its exact provenance is known and recorded, to ensure quality control. We follow the path of our steel from the mine to the mill, and on to our factory. These billets are initially ‘gun drilled’ and honed. The precise outer profile is then turned, using the bore axis as a reference, to ensure concentricity and hence even wall thickness. This attention to detail and the precision process translates into an extremely accurate barrel tube.

The barrel tubes are bonded using a specialist structural adhesive into the monobloc breech section, and the joint lines are laser welded and cleaned off flush, to give an invisible join and a continuous metal surface. The monobloc system of constructing barrels is preferred because this method enables the accuracy, precise alignment and convergence required for a modern performance gun.

The barrel assembly is uniquely bonded with a structural adhesive system at room temperature, which avoids distortion through heating and allows for the adhesive to be ‘cleaned up’ before curing. The structural adhesive is used extensively in the Formula One, Aerospace and Space industries to name but a few. This process omits the additional, labour intensive and dirty stage of ‘clean up’ after tinning. The inter-rib replaces the individual side ribs and passes between the two barrels as a single piece. This makes the assembly very accurate and rigid. Bonding is a process where we have been able to employ the latest in adhesive bonding processes, also found in the aerospace and Formula One industries.

Through independent testing both at Loctite Henkel and at the University of Cambridge Engineering Department, the strength of the barrel construction has been proven as strong, if not stronger, than traditional methods.

Another advantage of this innovative methodology is the reduction of corrosion, initiated from the flux used in the traditional construction method. Further, if the flux is not cleaned off appropriately, then this can negatively affect the barrel blacking process, and if the solder join is not complete, then there is an opportunity for corrosion between the barrels and the ribs. None of these failure modes exist with the Gallyon Inter-Rib system and bonding methodology.

The Gallyon barrels have a long forcing cone to accommodate steel shot.

The barrels have been blacked to the highest standard, using the traditional method.

The barrel bores are not chromium plated due to the high element of chrome in the material. Chromium surface plating of the barrel bore introduces a variable that can compromise accuracy.

Key features of the Gallyon barrels:

Choice of either 29- or 30 -inch barrels that are precision machined using a multi-axis CNC turning centre from solid billets of chromium molybdenum steel.

Barrels are assembled using a unique patented [United Kingdom Patent No. 2596583] Gallyon ‘Inter-Rib System’, a technologically advanced innovative system that provides an accurate, repeatable, rigid barrel assembly with precision convergence of barrel tubes.

Accurately defined barrel tube profile that provides unparalleled accuracy, straightness, concentricity between the Outside Diameter and that of the Inside Diameter, which provides a consistent wall thickness for exceptional performance, handling characteristics and aesthetic.

Solid, tapered, game-style top rib with optically matted top surface that gives a strong sightline.

Front bead sight in either stainless steel [silver] or aluminium bronze [soft gold].

76mm (3 inch) chambers with long forcing cones, London proved for High Performance Steel shot.

Forcing cones designed for optimum patterning of lead, steel and other shotgun shot materials.

Each gun is supplied with four stainless steel, flush-fit, Gallyon designed, interchangeable chokes, with a range of constrictions to choose from.

Performance coatings are available as an optional extra.

Titanium chokes are available as an optional extra, with or without performance coatings.

Traditional English barrel blacking.

Notes on Convergence of tubes in double-barrelled shotguns

Gun barrels are made with greater wall thickness at the breech than the muzzle. This is because the pressure produced by the cartridge is much higher near the breech than for the rest of the barrel. Hence when two tapering tubes are brought together, the bores at the muzzles are closer together than at the breech so that they converge.

The convergence can be controlled by the way the tubes are fixed together. Convergence would at first sight seem to mean that the two tubes would shoot across each other. However, projectiles do not follow the initial line of sight down the bore because the gun is moved both horizontally and vertically by recoil. If the right barrel of a side-by-side gun is fired, the line of force of recoil is on the right-hand side of the centre of mass of the gun. This causes the muzzle to start to rotate slightly to the right as the shot moves down the barrel. When the shot leaves the barrel, its direction of travel is to the right of where the barrel was pointing when the trigger was pulled. The opposite will occur with the left barrel. The same effect occurs in over-and-under guns in a vertical plane so that convergence is needed in these guns as well.

Shotguns throw a spread of pellets so that there is no precise centre to the pattern produced. A normal degree of convergence will be satisfactory to cope with varying shot load and muzzle velocities, which will affect recoil and barrel time and hence point of impact. Exactly the same movements occur in double rifles, both side-by-side and over-and-under. Rifles shoot single bullets with much greater accuracy than a shotgun and have precise adjustable sights. Regulating the convergence of double rifles is a complex procedure of shooting and adjustment to get both barrels to group together for particular bullet weights and muzzle velocities.

Don Custerson, Master Gun Maker and Gun Designer

Endorsement

“These are the best barrel tubes I have seen in my 48 years as a master barrel-maker.

“It’s vital that the barrels are truly round and concentric with the outside surface - not an easy thing to achieve - but your barrels have been correctly machined to great accuracy and consistency. They’re also straight, which sounds obvious but it’s difficult to do that.

“A thousandth of an inch at the shooter’s end means a foot or more at the target end. That’s why properly made barrels are at the heart of every fine gun.

“It’s very exciting that the future of the British, affordable, modern over-and-under shotguns is here, made in Cambridge UK by an excellent team of precision engineers guided by master gunmakers, put together by craftsmen, tried and tested in the field by the real shooters, and has proved itself to be good looking, accurate to point of aim and totally reliable.”

— Bill Blacker MAsR.G, Master barrel-maker

BILL BLACKER

Bill Blacker is the doyen of British barrel-makers, with a worldwide reputation for the highest standards of craftsmanship. He started his career in 1976, aged 16, as an apprentice with Holland & Holland, then went on to James Purdey & Son before setting up his own barrel making business.

Gallyon Interchangeable Choke Tube Technical Note

Gallyon over-and-under guns are fitted with flush-fit interchangeable, accurately machined chokes that are designed and made in house with the features and objectives listed below:

To be more robust than retro-fitted chokes, yet to work in combination and harmony with carefully profiled barrels in order to retain the fine balance and ‘lively’ handling characteristics of a best English gun.

A special thread form design to help keep the choke from coming loose.

Flush fitted so that the tube can be seen to be properly seated, sealed, and accurately located in the barrel tube socket.

A reinforced ring at the muzzle to avoid damage from choke keys.

70mm long with a smooth (N6) tapered bore to the muzzle.

Minimum change in diameter between the barrel bore and the entry diameter of the choke to avoid a less than desirable recess step that could adversely affect the ballistic performance and potentially enables the buildup of fouling or detritus elements.

Manufactured and inspected to tight tolerances focusing on restriction bore surface finish, roundness, diameter, and concentricity, as are the sockets in the barrels. Ensuring accuracy and consistency between different constriction sizes, with the objective to provide greater ballistic performance.

Made from high quality stainless steel as standard and additionally available in lightweight titanium alloy. Both material types are also available with PVD specialist performance coatings.

Clear laser engraving with choke constriction in thousands of an inch with UK and US designations. Marked STEEL SHOT up to half choke (modified) with Fleur de Lys and NOT FOR STEEL SHOT above half choke restriction.